KoldLok Split Integral - Model #3030

Applications

Installation in new or existing raised floor tiles prior to the installation of racks or cabinets containing computer and communication equipment.

Features

KoldLok is a permanent airflow sealing solution which will accept perpetual cabling1 changes without requiring technician training, policing, or labor to cut, scribe, re-install, reposition, or modify any part of the grommet.

KoldLok is the best2 low cost solution for achieving the hardware air intake temperature and humidity conditions required for maximum reliability and performance by computer and communication manufacturers.

The KoldLok system of overlapping, offset, multi-layer, interwoven bypass airflow closures utilizing KoldFilaments™ guarantees sealing effectiveness. (U.S. Patent No. 6,632,999.)

KoldLok avoids unnecessary investments in additional cooling capacity* by reducing bypass

airflow which increases both the effectiveness and usable capacity of existing cooling equipment.

KoldLok's 32 square inch usable cable area is sufficient to accommodate virtually all cabling requirements (typical cable fill area is less than 5 square inches, after plug has passed through).

KoldLok's sealing effectiveness enables standardization on one size of tile cutout reducing cost and tile inventory.

1 It is estimated that, on average, 25% of all raised floor openings are re-cabled quarterly.

2 Filaments are premium grade Nylon 6. Filaments made of styrene, ABS or polypropolene fall below KoldLok product standards.

*For a typical 10,000ft2 computer room with 170 cable

openings, preventing the 49,000 cubic feet per minute bypass airflow

loss through unsealed cable cutouts is equivalent to recovering the

output from five or more 20-Ton cooling units.

Specifications

Grommet is inherently self-sealing using a multilayer,

overlapping, and interwoven, bypass airflow closure system consisting of:

- Two opposing overlapping arrays of 0.010" diameter upper filaments

- Two opposing arrays of 0.020" diameter lower filaments

- 3,100 filaments per cross sectional inch

Grommet filaments are premium grade Nylon 6 ensuring bristle flexibility, compliance, and selfsealing recovery. Filaments are conductive with static dissipation properties.

Grommet and filaments safely bleed off any static build up on cables passing through the cable opening caused by high velocity airflow (triboelectric effect). Grommet is an integral part of the raised floor¹s static dissipation system providing 1 GigaOhm of resistance.

Grommet shall achieve 100% bypass airflow sealing in areas undisturbed by cable penetrations at static pressures up to 0.10 inches of water column. When penetrated by four 1/2" cables, sealing is 100% effective at the static pressure required to cool up to 3 kW/cabinet with a 96% sealing effectiveness at a static pressure of 0.10".

Grommet contains no loose or partially fastened parts, which can become separated, fall through the raised floor, tent, or be kicked out of position.

Grommet is a heavy duty, molded, high impact resistant polypropylene

housing with a wide trim

lip to provide a bumper to inhibit equipment casters from falling through

raised floor openings and to allow imprecise tile cutting.

Grommet metal components are anodized to resist corrosion caused by high humidity and are assembled with positive fasteners that will not pull through the plastic. Grommet is installed using four (4) provided self-drilling sheet metal screws without requiring predrilling.

Grommet satisfies NFPA 75 Section 5-4.4 requirement by self-dressing the raw metal edges of raised-floor tile cable cutouts.

DIMENSIONS & TILE CUTTING SPECIFICATIONS

Overall size: 11" x 8 1/4" x 1 5/8"

Grommet usable cable opening size: 8" x 4" *

Grommet total cable opening size: 8" x 5"

*Ensures easy passage of cable heads and power connectors including a 100 amp Hubbell™ power plug (or equivalent 4.125" x 4.125" connector).

Background

ELIMINATE BYPASS AIRFLOW

Unsealed cable openings allow 63% or more of bypass air losses in a

typical computer room. Excessive bypass airflow will reduce underfloor

static pressure to as low as 0.01" of water column. This is much

lower than the 0.025" required for cooling high heat densities

(> 1 kW/rack or cabinet). Unmanaged bypass air results in vertical

and zone hot spots and introduces significant cooling inefficiencies.

A CLEAR SOLUTION

The KoldLok Integral Raised-Floor Grommet automatically reseals raised-floor openings, permanently solving bypass airflow problems.

Preparation:

Cutting Raised Floor Tiles

Each raised floor tile manufacturer provides instructions to properly and safely modify their products. Installers must be familiar with and observe tile manufacturer’s recommendations with regard to applicable tools, cutting procedures, the design load capacity of the cut tile, and any additional underfloor support requirements for cut raised floor tiles.

*IMPORTANT: Data center best practices indicate that tiles should not be cut within the raised floor environment in order to protect equipment from harmful particulates. However, quick clean up of any debris or loose particulates is always recommended. Clean the tile and bottom surface of the grommet using an alcohol wipe or a clean cotton cloth, damp with a solution of at least 50 percent isopropyl alcohol.

HELPFUL TIP: When choosing your cleaning cloth, do not use fabric or paper that will disintegrate or leave particles that could interfere with the adhesive or contribute to airborne contamination.

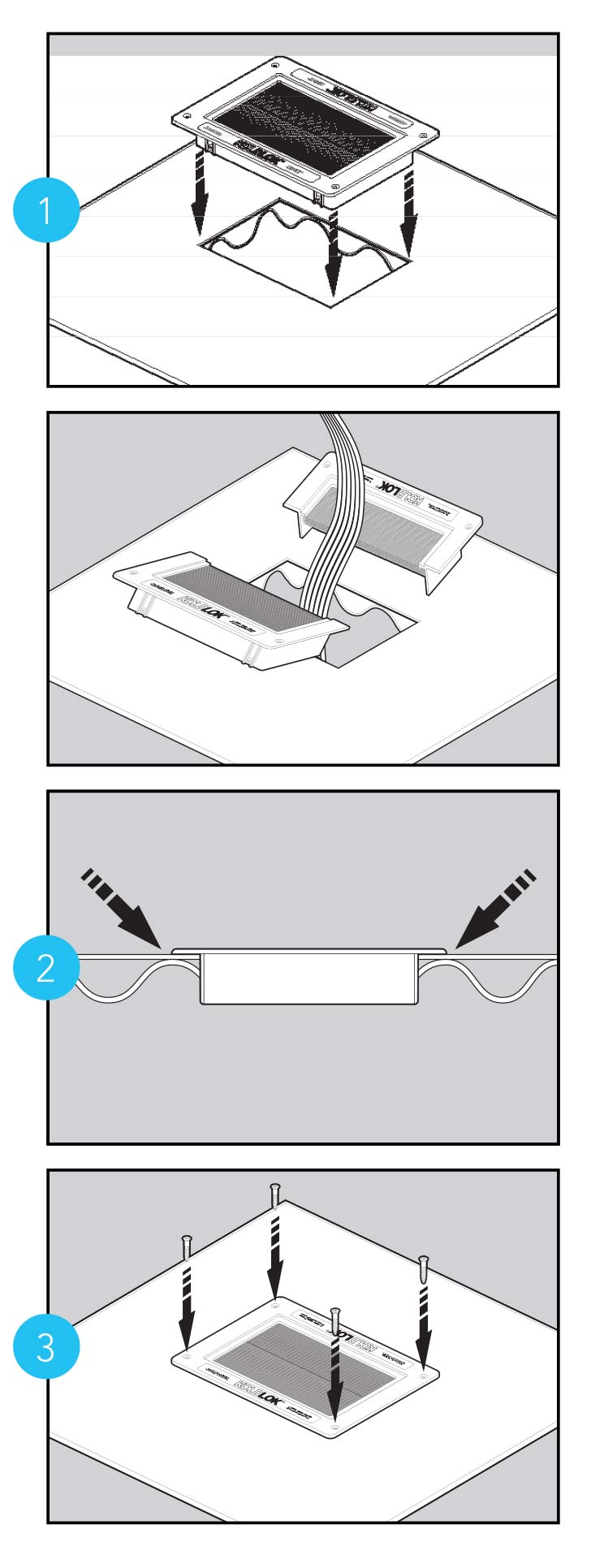

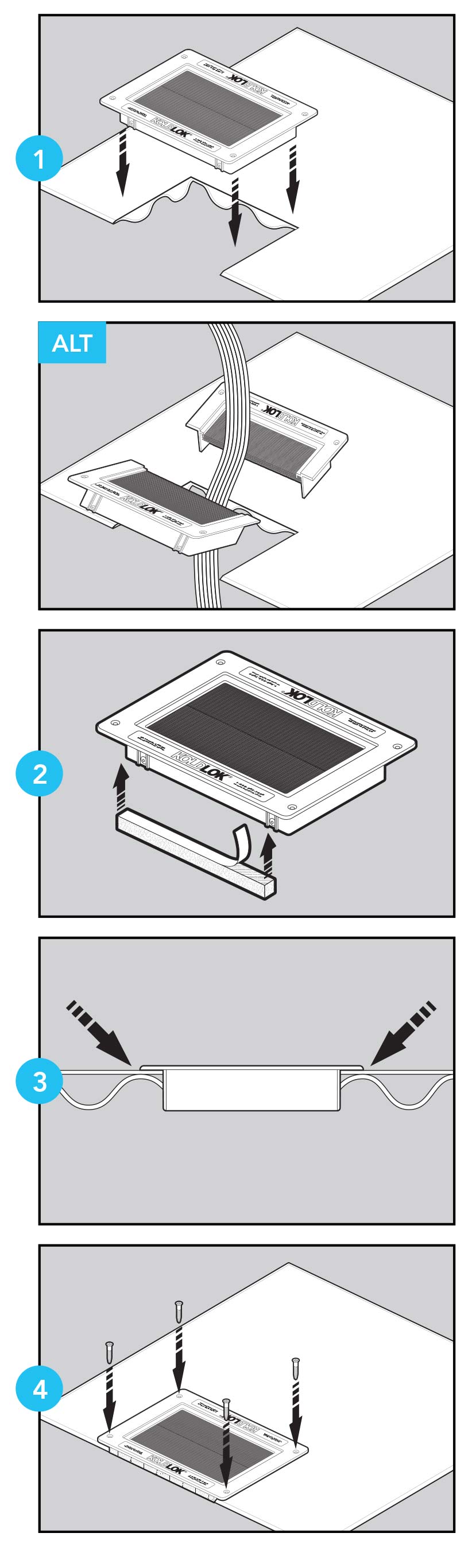

Installation on the Tile Interior

- Make a 9.25" x 6.75" cutout (235 mm x 172 mm) in the floor tile. Ensure that any burrs that resulted from cutting the floor tile have been removed. It is not necessary to dress the cutout when installing a KoldLok® Integral or Split Integral Raised Floor Grommet.

- Test-fit KoldLok® to the floor tile by making the flange flush with the topside of the floor tile. Ensure there is no binding and that the fit is even on the Grommet.

- With the Grommet properly placed in the floor tile, fasten it securely to the floor tile using the selftapping screws. Do not over-torque the screws.

Installation on the Tile Edge

(Long Edge of Grommet)

In the absence of a supporting floor tile flange, edge-mount installations require a foam insert on the open side of the cut to serve as an air block. If your floor tile has been cut on three sides only, providing one open edge, the Grommet must be installed with the supplied foam strip inserted into the molded depression on its underside.

- Provide a 9.25" x 7.5" cutout (235 mm x 191 mm) in the floor tile. Ensure that any burrs that resulted from cutting the floor tile have been removed. It is not necessary to dress the cutout when installing a KoldLok® Integral or Split Integral Raised Floor Grommet.

- Stretch the supplied foam strip to fill the 9” depression on the underside of the Grommet.

- Test-fit KoldLok® to the floor tile, with flange on the topside of the floor tile. Ensure there is no binding and that the fit is even on the Grommet.

- With the Grommet properly placed in the floor tile, fasten it securely to the floor tile using the self-tapping screws. Do not over-torque the screws.

Installation on the Tile Edge

(Short Edge of Grommet)

The KoldLok® Integral and Split Integral Raised Floor Grommets may also be installed with the short side mounted along the floor tile edge. Make a 6.75" x 10.25" cutout (172 mm x 260 mm). Follow the same preparation and fastening steps as above.

General Information

Effective Installation of CablesIn order to minimize any air loss from under the raised-floor plenum, allow for adequate slack in the cables. If the cables are under too much tension, the grommet filaments may be pulled apart, resulting in a V-shaped gap that will cause an increase in the volume of air escaping from under the raised floor.

Maintaining Proper Cooling of EquipmentFailure to follow computer manufacturer’s guidelines for maintaining proper cooling may result in the overheating of equipment. Ensure that there is adequate airflow to the intake side of the computer equipment or cabinets through devices such as perforated floor tiles or grates. Achieving proper airflow to the intake side of computer equipment and/or cabinets is the responsibility of the customer.

Shop NowContact us at products@dataclean.com for more information.